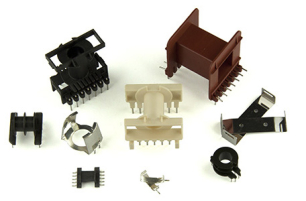

RM (Rectangular Modulus) Cores:

This requirement emerged in response to the increasing demand for coil formers featuring integrated pins, designed to facilitate efficient winding processes while enabling higher packing densities on printed circuit boards (PCBs).

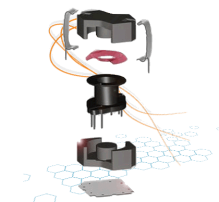

The cores are securely held in position by clamps which engage with designated recesses in the core base. This method eliminates the need for adhesive bonding in the assembly process, thereby enhancing ease of manufacture and ensuring reliable mechanical stability.

RM cores are also available without a central aperture. These solid cores possess a higher AL value and an increased cross-sectional area, making them particularly suitable for use in power transformer applications. Common types in this category include F47, F44, F45, and F5A. The enhanced magnetic properties and larger cross-section enable improved efficiency and performance in power transformation tasks.

RM cores are engineered to serve two primary applications:

-

Highly stable, ultra-low loss filter inductors and other inductors critical to resonance control (e.g., types F58 and P11). These cores are optimised to ensure exceptional stability and minimal energy dissipation, making them ideal for precision filtering and resonance-sensitive circuits.

-

Low-distortion broadband transmission inductors designed for low-level signal modulation (such as types F39, F10, and F9). These cores facilitate clean signal transmission across a wide frequency range, minimising distortion and preserving signal integrity in communication and transmission systems.

All cores are manufactured in strict accordance with the specifications outlined in IEC 431 and DIN 41980 standards. Furthermore, the coil formers conform to the requirements specified in DIN 41981, ensuring full compliance with recognised industry standards.