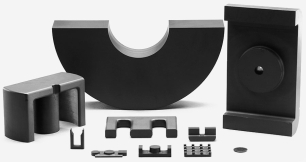

Ceramic Magnets (Hard Ferrite):

These magnets are manufactured primarily from barium or strontium compounds and were first developed in the early 1960s as a cost-effective alternative to the more expensive metallic magnets available at the time.

Characterised by their hard and brittle nature, they exhibit lower energy performance when compared to other classes of magnetic materials. Nevertheless, they remain highly popular and widely utilised across various industries due to their exceptional resistance to demagnetisation and corrosion, combined with their highly competitive pricing.

Ferrite magnets are produced through various manufacturing methods, including pressing, sintering, and injection moulding. These magnets are available in both anisotropic and isotropic forms.

Anisotropic ferrite magnets undergo an orientation process during manufacturing, aligning their magnetic domains in a specific direction. Consequently, these magnets require magnetisation aligned precisely with this predetermined orientation to achieve optimal magnetic performance.

In contrast, isotropic ferrite magnets are manufactured without any specific directional alignment of their magnetic domains. This absence of orientation allows them to be magnetised in any direction, offering greater flexibility in their application, albeit with generally lower magnetic strength compared to their anisotropic counterparts.

Applications of Ceramic Magnets

- Speaker Magnets

- DC brushless motors

- Magnetic Resonance Imaging (MRI)

- Magnetos used on lawnmowers and outboard motors

- DC permanent magnet motors (used in cars)

- Separators (separate ferrous material from non-ferrous)

- Used in magnetic assemblies for lifting, holding, retrieving and separating