Samarium Cobalt (SmCo):

Samarium Cobalt (SmCo) magnets belong to the Rare Earth category and have been commercially available since the early 1970s. These magnets are renowned for their exceptionally high magnetic strength combined with excellent thermal stability, which ensures consistent performance across a broad temperature range. Additionally, SmCo magnets exhibit strong resistance to corrosion, making them highly suitable for demanding environments.

The unique properties of SmCo magnets render them ideal for applications where exposure to extreme temperatures and harsh environmental conditions is a critical factor. Manufacturing of SmCo magnets is typically carried out through either sintering or compression bonding processes. These magnets are anisotropic, meaning they possess a preferred direction of magnetic orientation and can only be magnetised effectively along this axis.

To achieve full magnetic saturation, SmCo magnets generally require magnetising fields in the range of approximately 30 to 45 kilo-Oersteds (KOe). This precise magnetisation characteristic is essential to harness their optimal magnetic performance in specialised industrial and technological applications.

Features of Sintered SmCo

- The best temperature characteristics in the rare-earth magnet family

- Manufactured by powder metallurgical process involving the sintering of powder under vacuum.

- Both grades of SmCo5 and Sm2Co17, commonly referred to as 1:5 and 2:17 material are available.

- Good corrosion resistance and no special surface treatment required excellent for compact designs where high working temperature is a major concern. Grinding and slicing operations are possible

Application: applied to various electric motors, instruments, sensors, detectors, radar, and other high-tech equipment.

Attributes of Samarium Cobalt Material

- High resistance to demagnetization

- High energy (magnetic strength is strong for its size)

- Good temperature stability

- Expensive material (cobalt is market price sensitive)

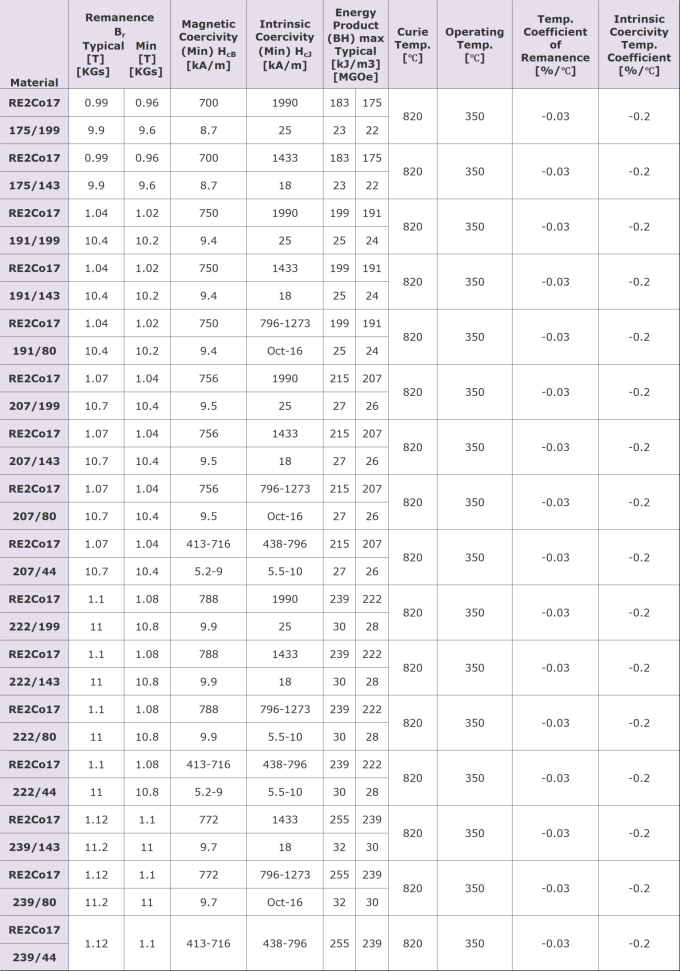

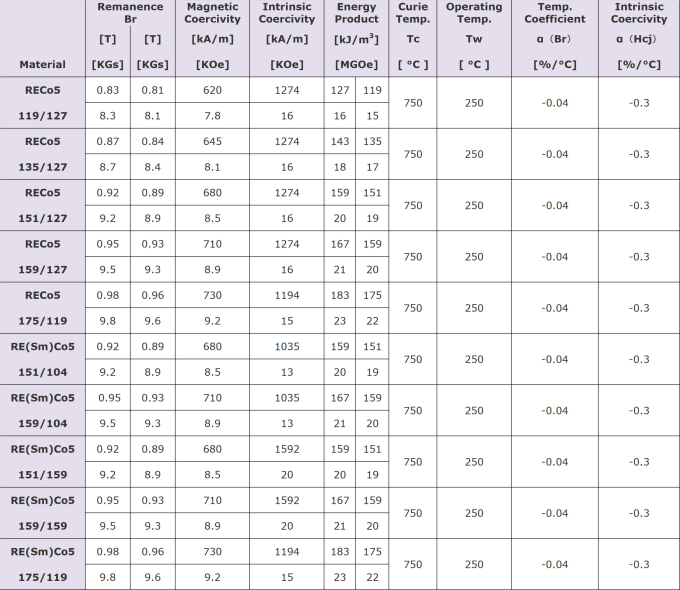

Magnetic property parameters of Sintered Smco5

Note: Curie temperature and temperature coefficient are for reference only.

Magnetic property parameters of Sintered Sm2co17